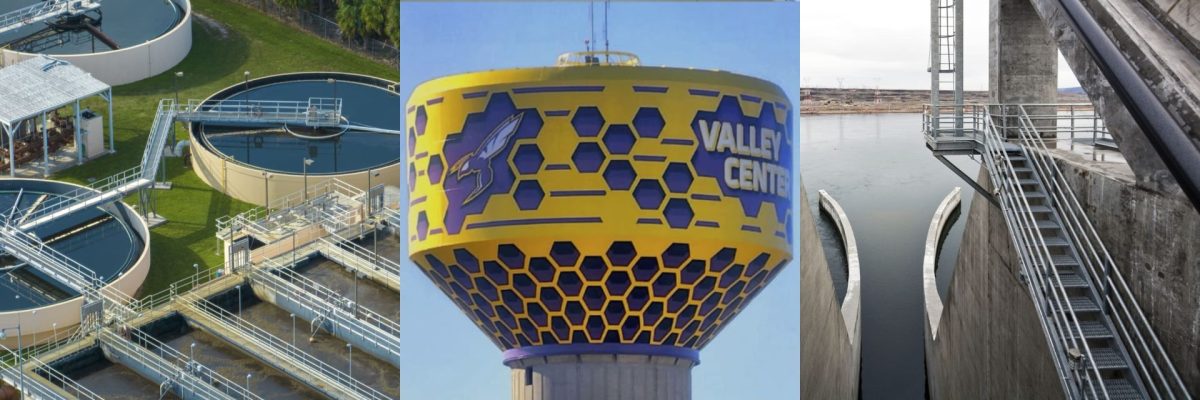

Different Types of Water Assets that Need Protective Coatings

Posted on January 29, 2025 by Brent Phillips

Water infrastructure plays a crucial role in our daily lives, providing clean, safe water for consumption and various other purposes. However, these vital assets are constantly exposed to harsh environmental conditions and corrosive elements that can lead to deterioration over time.

Protective coatings have emerged as an essential solution for safeguarding these assets and extending their lifespans. Let’s explore the different types of water assets that benefit from protective coatings and why they are important.

Water Storage Tanks

One of the most common water assets requiring protective coatings is water storage tanks. These structures, whether made of steel or concrete, are susceptible to corrosion, contamination, and leaks.

Applying NSF/ANSI 61, an approved epoxy and polyurethane coating, creates an impermeable barrier that prevents corrosion and ensures the water remains safe for consumption. These coatings protect the tank’s structural integrity and help maintain water quality.

Pipelines and Distribution Systems

The extensive network of pipes transporting water from treatment facilities to homes and businesses is another critical asset that benefits from protective coatings. These pipelines face challenges such as internal corrosion, external environmental factors, and potential chemical reactions with the water they carry. Specialized coatings can provide:

- Corrosion resistance

- Improved flow efficiency

- Prevention of biofilm formation

- Extended service life

Water Treatment Facilities

Water treatment plants contain a variety of equipment and structures that require protection from corrosive chemicals and constant exposure to water. These assets include:

- Clarifiers and sedimentation tanks

- Filters and filter beds

- Chemical storage tanks

- Pump stations

Protective coatings in these facilities must withstand aggressive chemicals, abrasion, and continuous immersion. High-performance epoxy and ceramic epoxy coatings are often used to provide long-lasting protection and ensure the efficient operation of treatment processes.

Wastewater Infrastructure

Wastewater systems present unique challenges due to the highly corrosive nature of sewage and the presence of hydrogen sulfide gas. Assets in this category that require protective coatings include:

- Sewer pipes and manholes

- Lift stations

- Digesters and aeration tanks

- Secondary containment areas

Specialized coatings for wastewater applications must offer excellent chemical resistance, abrasion resistance, and the ability to withstand high levels of hydrogen sulfide gas. These coatings not only protect the infrastructure but also help control odors and prevent the deterioration of concrete and steel surfaces.

Dams and Reservoirs

Large-scale water assets like dams and reservoirs also benefit from protective coatings. These structures face challenges such as water pressure, erosion, and potential chemical attack from contaminants in the water. Coatings for dams and reservoirs must provide:

- Waterproofing

- Crack bridging capabilities

- Resistance to hydrostatic pressure

- Protection against freeze-thaw cycles

Appropriate coatings can significantly extend the lifespan of these critical infrastructure components, ensuring a reliable water supply for communities.

Water Towers and Elevated Tanks

Water towers and elevated tanks are iconic structures that serve as functional water storage and community landmarks. These assets are exposed to varying weather conditions and require protection both inside and out. Exterior coatings must provide:

- UV resistance

- Color retention

- Protection against atmospheric corrosion

Interior coatings, on the other hand, focus on preventing corrosion and maintaining water quality. Modern fluoropolymer coatings have revolutionized the protection of these structures, offering superior durability and aesthetics.

Hiring a Protective Coating Application Expert

Protective coatings are vital in preserving and extending the life of various water assets. From storage tanks to treatment facilities and from pipelines to dams, each type of asset requires specialized coating solutions to address its unique challenges.

By hiring a protective coating application expert, you invest in a high-quality team of professionals who will know about the substrate and what protective coatings work best. Providing water utilities and city municipalities with the longevity, efficiency, and safety of their water infrastructure will ultimately benefit the communities they serve.

To start today, contact the sandblasting and protective coating experts at Cunningham Inc. Their team of professionals can also assist you with meeting any annual coating inspection at (620) 848-303